We also support you with peripheral system components and integrate them into the system concept:

Water Treatment Plants

Good pre-treatment quality depends essentially on good rinsing. Rinsing with fully demineralised water is often necessary, and the deionised water systems are used to recirculate the water. The water treatment plant is optimally tailored to your pre-treatment system.

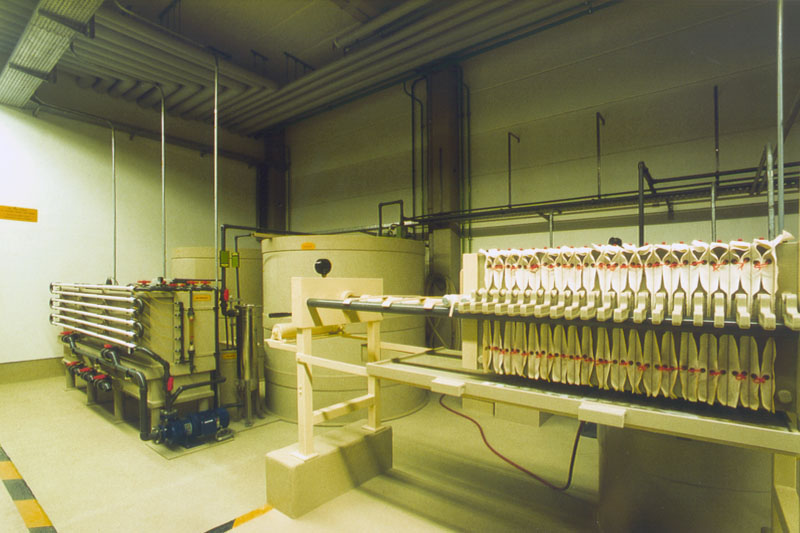

Batch waste-water treatment plant

Waste-water Treatment Plants

Waste-water from pre-treatment and painting plants must not be discharged untreated – neither via the public sewer system into municipal sewage treatment plants nor into natural bodies of water. We have the right waste-water system solution for your pre-treatment and painting plant.

Fully demineralised water plant and batch waste-water treatment system

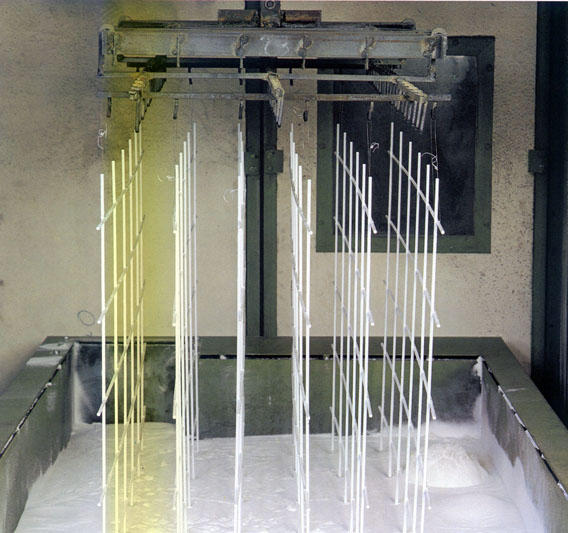

Paint Stripping Systems

We plan, design and manufacture your paint stripping system for the removal of paint from product carriers or faulty coated parts.

Paint Stripping System

Crack Testing and Penetration Systems

Aircraft engine parts, landing gear parts and wheel rims – to name but a few – must be inspected at regular intervals. Safety is the trump card in crack detection!

Crack Testing and Penetration System

Cooling Zones

are used where it is necessary to reduce the workpiece temperature within a short period of time, such as, for example, after drying retained water or after baking paint or sintering powder paints.

Cooling Zone

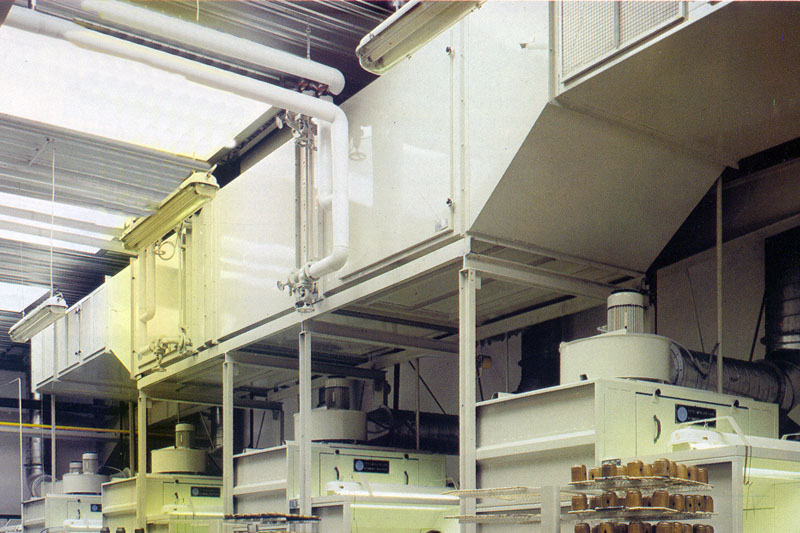

Exhaust Air Systems

for compliance with the MAK (maximum workplace concentration) values at the workplace or for the removal of solvents during the flash-off process within the workshop. The exhaust air systems can be equipped with heat recovery, if required.

Exhaust Air System

Vortex Sintering Systems

are needed when particular wear- and impact-resistant surface protection is required. Vortex sintering is environmentally friendly. We plan, design and manufacture vortex sintering systems for manual coating and for fully automatic operation.

Vortex sintering baths

Thermal Afterburning Systems (TAS)(TNV)

These are used where the Federal Immission Control Act stipulates that, due to the amounts of solvents involved, solvent emissions must be minimised.

In the TAS, the solvent-containing exhaust air is fed to the reaction chamber in which the solvents contained are burnt. The energy released in the process is recovered and fed to the dryer, the pre-treatment system or the supply air system, depending on the requirements of the system conditions.

Thermal Afterburning (TAS)

Supply Air Systems

These are used in order to return the air extracted through the

- pre-treatment systems

- spray cabins

- flash-off zones

- cooling zones

- dryers

- exhaust air systems

to the plant and thus to achieve a balanced air supply again.

We offer you supply air systems with

- heating (with your available energy)

- cooling equipment

- humidifying or dehumidifying equipment

- filtering equipment

Zuluftanlage